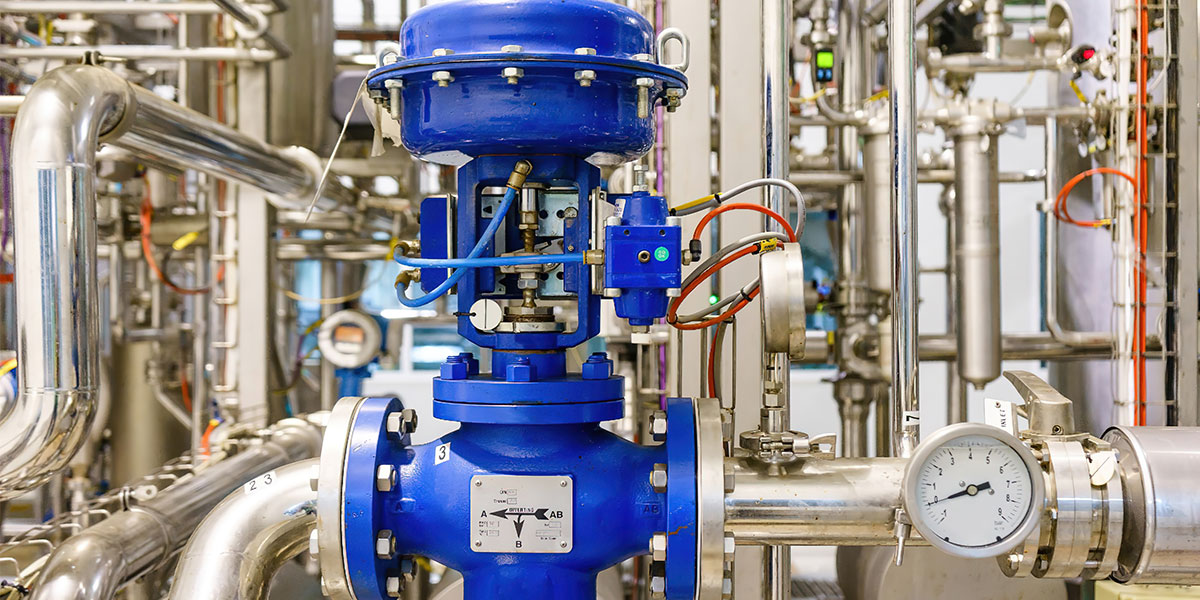

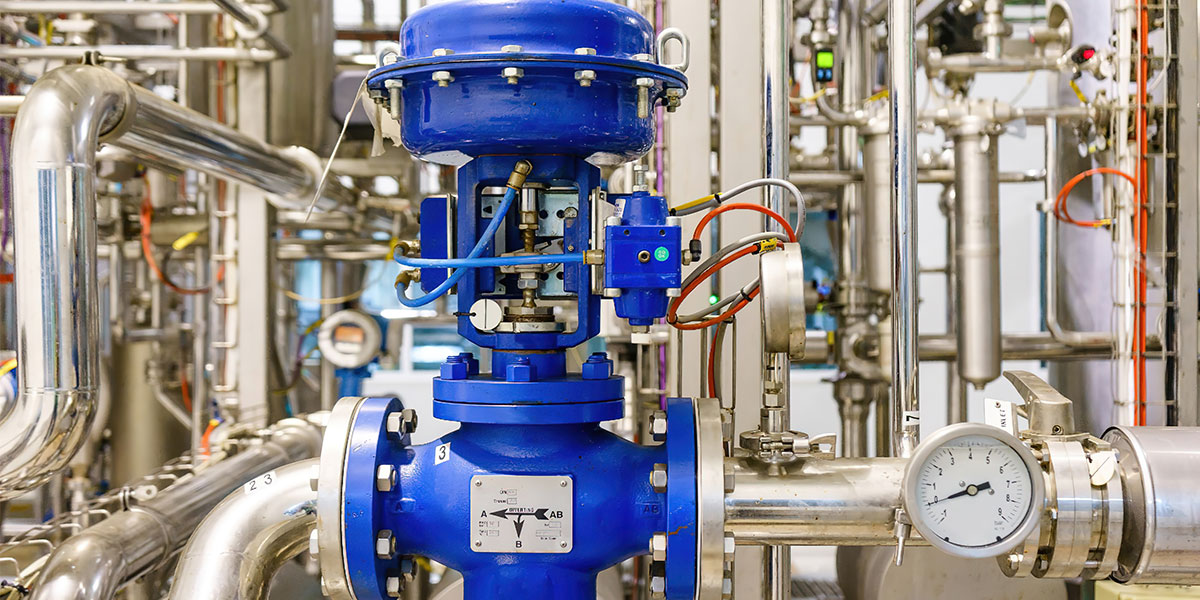

In extreme environments, application and critical service, the effects of leaking valves are likely to be detrimental, hence product pressure testing is critical to ensuring product integrity. Every client would like to know that the valves being commissioned on their site have been comprehensively pressure tested. Valves play a decisive role in industries such as chemical or oil and gas. A dysfunctional valve can, for example, lead to fire disaster causing major loss in the petroleum industry. The compliance with applicable standards and regulations is therefore crucial in order to ensure safety and performance.

Gulf Valve specialises in a variety of types and sizes that are tested within our purpose designed test cells at prescribed pressures using different fluids, including inhibited water, in accordance with API 6D and ISO 14313 specifications. These procedures, which are often the certification checks of a series of tests taken before repainting, verifies the strength of critical valve components including body, bonnet, ends and seats.

Hydrostatic testing also evaluates the integrity of the valve’s pressure retention and seat sealing capacity when exposed to internal pressures encountered under normal or abnormal environments during its lifespan. Leakage is measured on a pressure gauge and or recorded automatically with a digital chart recorder device which monitors pressure loss over time.

Utilising high-pressure pumping systems, valves and other components can be tested underwater in experimental pipelines at internal gas pressures of up to 20,000psi. Any leakage, however small, is detected and measured by fully calibrated micromanometers.

A variety of valves of different sizes and types can be tested with tracer gases including methane or helium, or a mix of 99% nitrogen and 1% helium. Using our high-sensitivity mass spectrometer, external leakage rates as low as one billionth of a cubic centimetre per second can be detected and pinpointed.

Gulf Valve Management system is the one location for all your valve population management needs. Your valves are managed in our central database and will soon be available digitally on our website. Our progressive management systems can support the customers needs for easy access and can be readily available when needed.

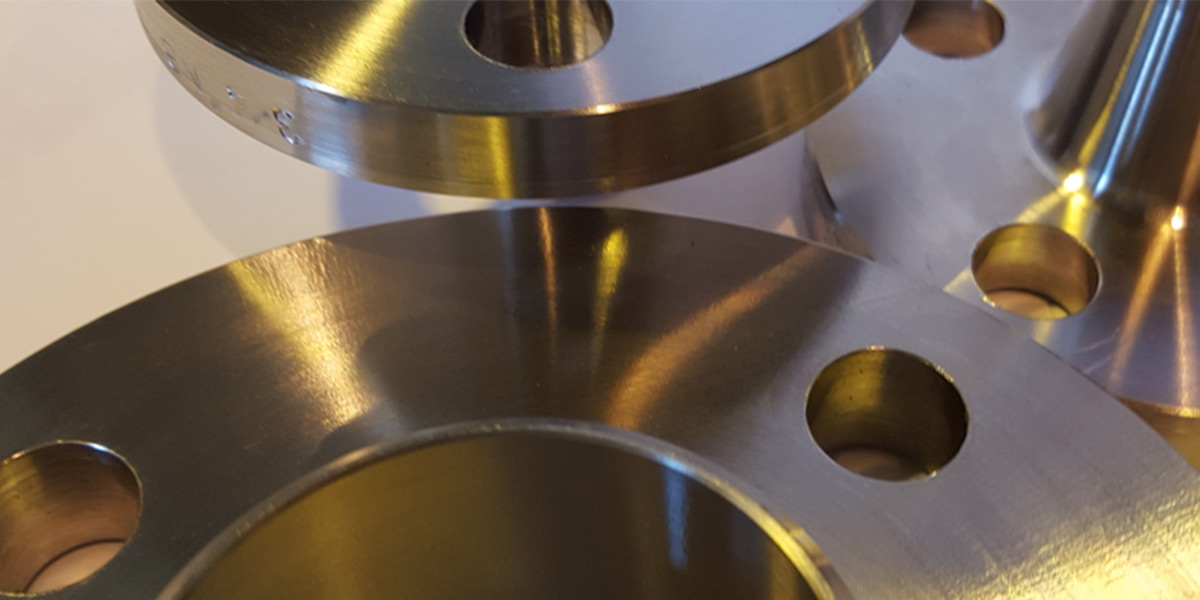

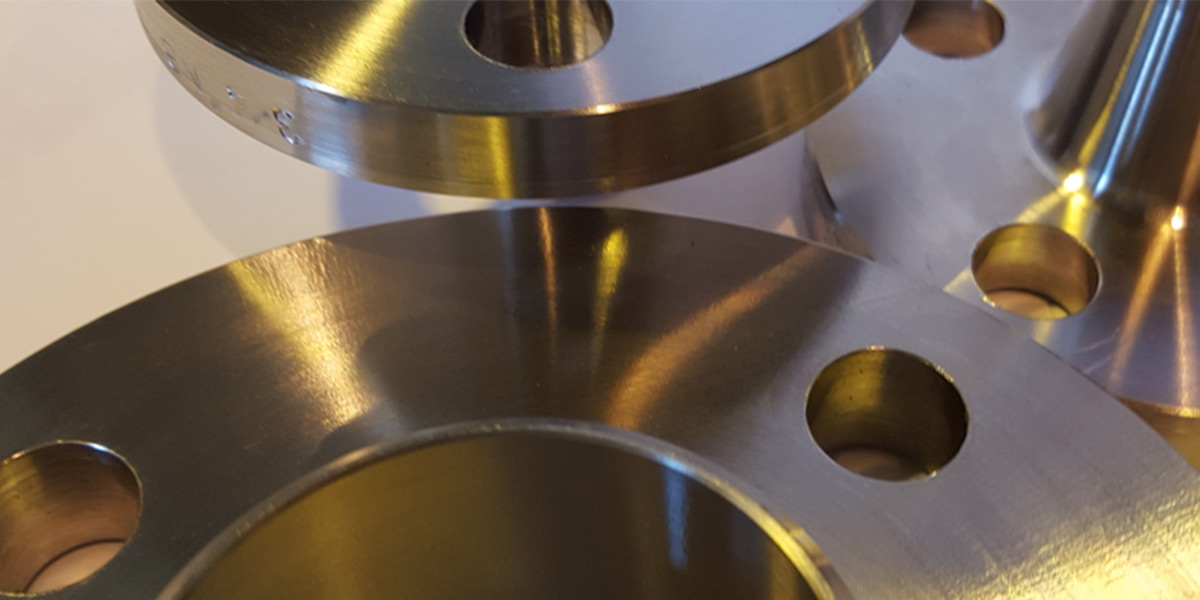

Gulf Valve is more than an industrial valve shop. We also offer full service, small batch Manual & CNC machining. CNC machining involves computerised machines set to process materials for industrial applications. Along with manual machining, our CNC services provide precise manufacturing via mills, lathes, and more. Focusing on small batch CNC machining allows us to offer quick turnaround on high-precision, complex machining.

We offer a comprehensive range of offshore and on-site welding and fabrication solutions for any shutdown, preventative maintenance and installation work scope. Our repair and modifications scope includes in-line weld repair of valve/pipeline end connections, valve seal areas and the removal / Reinstatement of welded in-line valves or pipeline flanges. We also offer structural fabrication, fabrication of spools, pre and post weld heat treatment and as well as other bespoke welding solutions.

At Gulf Valve we have specialised and trained personnel to handle Installation, testing and commissioning on start ups, shutdowns and replacement of plant and equipment.

Gulf Valve Piping and Controls is specialised in piping and mechanical works: engineering, prefab and on-site construction. Our offering includes maintenance of piping and a variety of installations, with Carbon Steel, stainless steel, aluminium, GRE, monel and other materials.

Gulf Valve has a dedicated workshop for prefabrication of piping works, structural steel, such as skids, strainers, pulling heads for the offshore industry, pressure vessels and headers.

Gulf Valve boast a robust warehousing facility which comes fully equipped with:

Our facility also offers vast storage space to house company and client stock long term. Our stock is fully catalogued and electronically traced to ensure fast access and guarantee 100% traceability of our client’s assets as well as our own.

To minimise downtime and to keep your products flowing, Gulf Valve has a complete line of valve sealants, lubricants, penetrants and packings to ensure your valves will operate at maximum efficiency. Regardless of your valve type or the fluid in your lines, We distribute and stock a wide range of valve maintenance products that are formulated to exacting standards to accommodate all your needs and working environments.

From general purpose sealants for use where hydrocarbon resistance is important to specialised hydrogen sulphide, sour crude resistance is a requirement. Our distributed line of lubricants and sealants are formulated from blends of vegetable oils, synthetic oils and additives that are both chemically stable and naturally corrosion resistant.

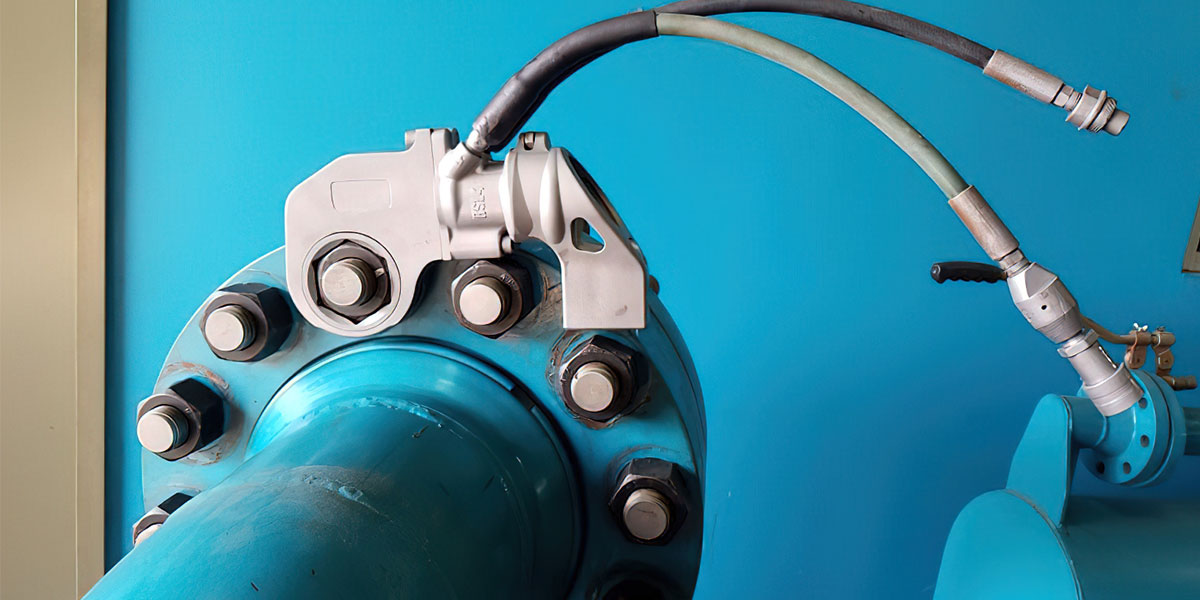

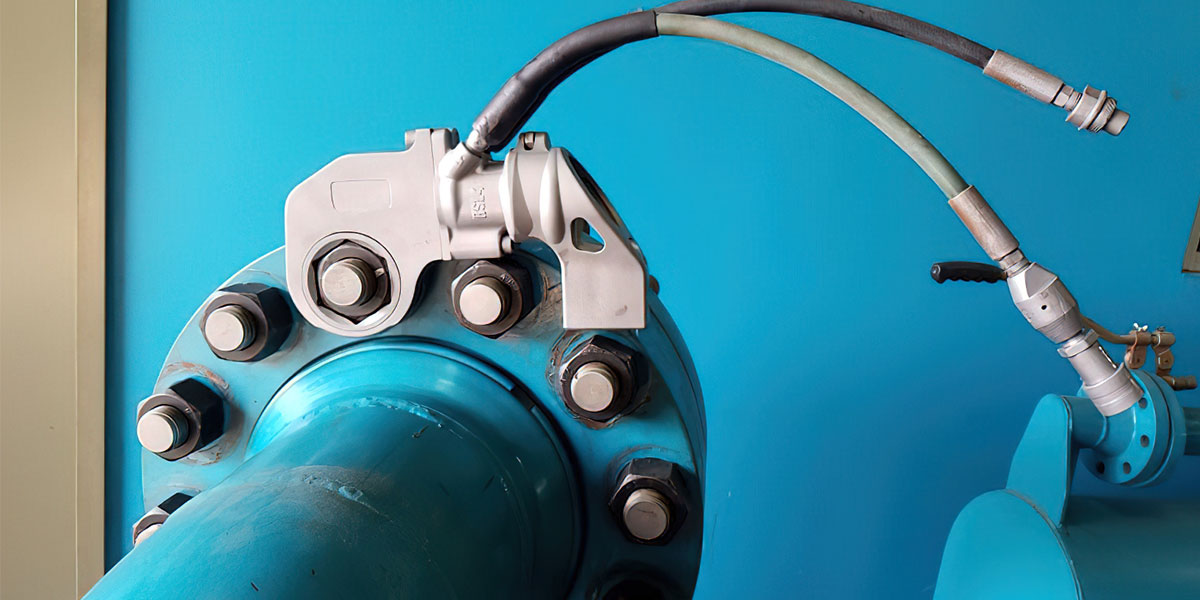

To assist all your controlled bolting torquing or Joint Integrity needs we offer a full range torque equipment for hire that incorporates hand torque Tools – spigot and ratchet type wrenches, sockets, open ended crows foot connections, ring spanner type connectors.

Hydraulic Torque Tools – Low profile torque heads, square drive c/w reaction arm torque units with a full range of links & sockets to cover all bolting sizes.

Air & Electrical Driven Hydraulic Torque Pumps – Complete with hoses, filter lube regulators & auxiliary fittings with a working pressure of 10,000 psi.

Pneumatic Torque Tools – Single Speed and dual speed square drive J-Guns complete with calibrated filter regulator lubricator system, full range of sockets.

Electrical Torque Tools – Lithium Battery powered square drive torque guns complete with a range of sockets.

Tensioning Equipment – Tensioning Pumps, Hoses, connections, we offer both metric and imperial standard sized tensioners and oversized tensioners for coated bolts.

Our torque equipment is regularly inspected to ensure it is kept at the highest standards and within calibration so when it’s required it will always be ready to go at a moment’s notice to meet the demands of a dynamic market.

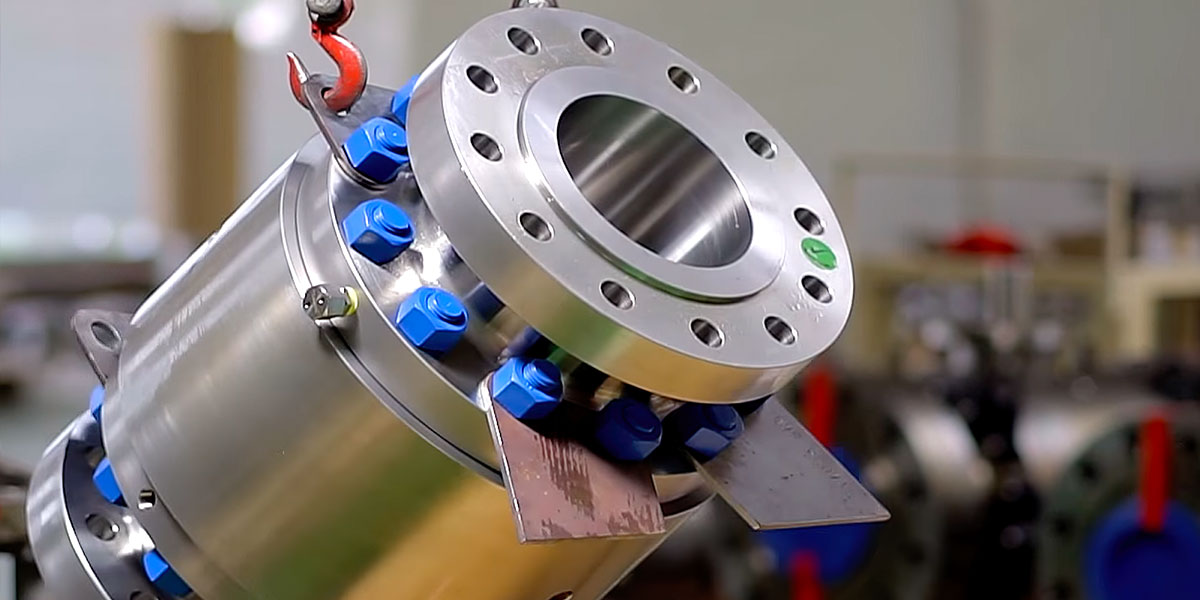

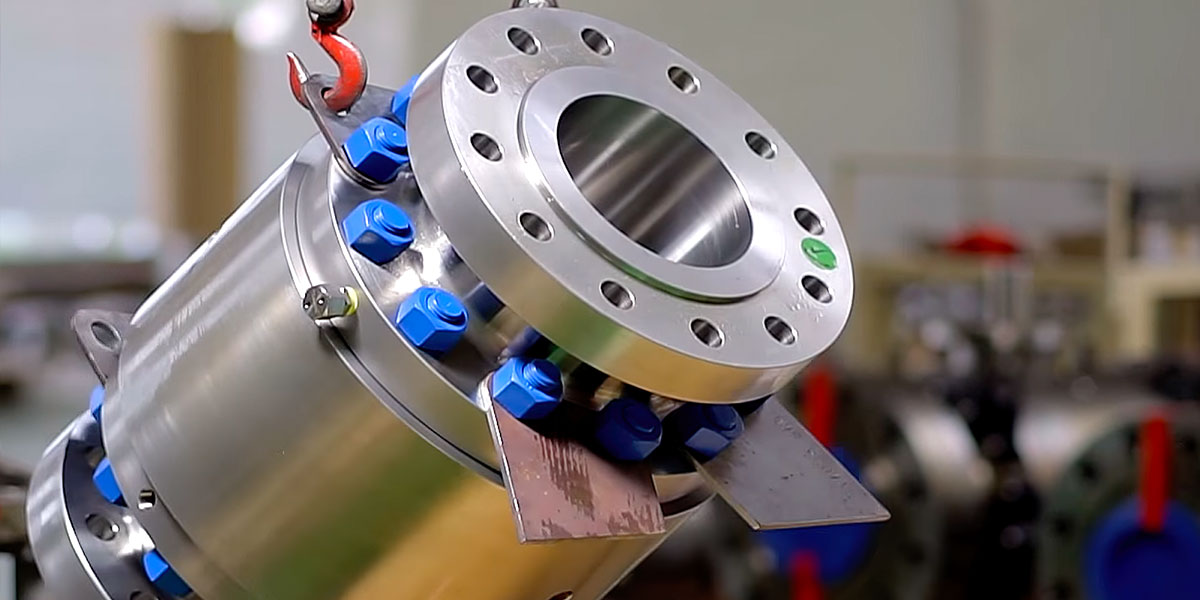

Our modern facility is equipped with the latest tooling and technology to repair and recertify valves & relating equipment to optimal working standard. Our expansive repair space is furnished to tackle various circumstances of valve overhaul, testing, valve automation and modification.

We offer a quick-turnaround service with overtime working to ensure deadlines are met to best serve our clients and their respective assets. At Gulf Valve, we promote a proactive service as opposed to a reactive one when it comes to repair, maintenance and future performance of the valve; our intuition and understanding of the service and its long term effect on the materials, structure and exposed surfaces advocates us to recommend upgrades to boost product durability and performance to increase their life-cycle to the optimum.

Our knowledge and innovation of industry equipment allows us to modify valve design when necessary, boosting their versatility or sometimes adapting them for a different service/purpose altogether to the benefit of the project. These modifications can take place either on-site or at one of our approved machine shops, all design & calculation activities are controlled and executed by the engineering team at Gulf Valve.

We can modify existing stock to promote considerable cost savings as well as the possibility to minimise system downtime by eliminating factory lead time scenarios to produce prompt and according solutions.

In addition to the standard API & EN hydrostatic and pneumatic valve leak testing, Gulf Valve can offer the most advanced testing to meet the severest of applications and specifications of our customers. Our vast range of test capabilities are as follows:

In extreme environments, application and critical service, the effects of leaking valves are likely to be detrimental, hence product pressure testing is critical to ensuring product integrity. Every client would like to know that the valves being commissioned on their site have been comprehensively pressure tested. Valves play a decisive role in industries such as chemical or oil and gas. A dysfunctional valve can, for example, lead to fire disaster causing major loss in the petroleum industry. The compliance with applicable standards and regulations is therefore crucial in order to ensure safety and performance.

Gulf Valve specialises in a variety of types and sizes that are tested within our purpose designed test cells at prescribed pressures using different fluids, including inhibited water, in accordance with API 6D and ISO 14313 specifications. These procedures, which are often the certification checks of a series of tests taken before repainting, verifies the strength of critical valve components including body, bonnet, ends and seats.

Hydrostatic testing also evaluates the integrity of the valve’s pressure retention and seat sealing capacity when exposed to internal pressures encountered under normal or abnormal environments during its lifespan. Leakage is measured on a pressure gauge and or recorded automatically with a digital chart recorder device which monitors pressure loss over time.

Utilising high-pressure pumping systems, valves and other components can be tested underwater in experimental pipelines at internal gas pressures of up to 20,000psi. Any leakage, however small, is detected and measured by fully calibrated micromanometers.

A variety of valves of different sizes and types can be tested with tracer gases including methane or helium, or a mix of 99% nitrogen and 1% helium. Using our high-sensitivity mass spectrometer, external leakage rates as low as one billionth of a cubic centimetre per second can be detected and pinpointed.

Gulf Valve Management system is the one location for all your valve population management needs. Your valves are managed in our central database and will soon be available digitally on our website. Our progressive management systems can support the customers needs for easy access and can be readily available when needed.

Gulf Valve is more than an industrial valve shop. We also offer full service, small batch Manual & CNC machining. CNC machining involves computerised machines set to process materials for industrial applications. Along with manual machining, our CNC services provide precise manufacturing via mills, lathes, and more. Focusing on small batch CNC machining allows us to offer quick turnaround on high-precision, complex machining.

We offer a comprehensive range of offshore and on-site welding and fabrication solutions for any shutdown, preventative maintenance and installation work scope. Our repair and modifications scope includes in-line weld repair of valve/pipeline end connections, valve seal areas and the removal / Reinstatement of welded in-line valves or pipeline flanges. We also offer structural fabrication, fabrication of spools, pre and post weld heat treatment and as well as other bespoke welding solutions.

At Gulf Valve we have specialised and trained personnel to handle Installation, testing and commissioning on start ups, shutdowns and replacement of plant and equipment.

Gulf Valve Piping and Controls is specialised in piping and mechanical works: engineering, prefab and on-site construction. Our offering includes maintenance of piping and a variety of installations, with Carbon Steel, stainless steel, aluminium, GRE, monel and other materials.

Gulf Valve has a dedicated workshop for prefabrication of piping works, structural steel, such as skids, strainers, pulling heads for the offshore industry, pressure vessels and headers.

Gulf Valve boast a robust warehousing facility which comes fully equipped with:

Our facility also offers vast storage space to house company and client stock long term. Our stock is fully catalogued and electronically traced to ensure fast access and guarantee 100% traceability of our client’s assets as well as our own.

To minimise downtime and to keep your products flowing, Gulf Valve has a complete line of valve sealants, lubricants, penetrants and packings to ensure your valves will operate at maximum efficiency. Regardless of your valve type or the fluid in your lines, We distribute and stock a wide range of valve maintenance products that are formulated to exacting standards to accommodate all your needs and working environments.

From general purpose sealants for use where hydrocarbon resistance is important to specialised hydrogen sulphide, sour crude resistance is a requirement. Our distributed line of lubricants and sealants are formulated from blends of vegetable oils, synthetic oils and additives that are both chemically stable and naturally corrosion resistant.

To assist all your controlled bolting torquing or Joint Integrity needs we offer a full range torque equipment for hire that incorporates hand torque Tools – spigot and ratchet type wrenches, sockets, open ended crows foot connections, ring spanner type connectors.

Hydraulic Torque Tools – Low profile torque heads, square drive c/w reaction arm torque units with a full range of links & sockets to cover all bolting sizes.

Air & Electrical Driven Hydraulic Torque Pumps – Complete with hoses, filter lube regulators & auxiliary fittings with a working pressure of 10,000 psi.

Pneumatic Torque Tools – Single Speed and dual speed square drive J-Guns complete with calibrated filter regulator lubricator system, full range of sockets.

Electrical Torque Tools – Lithium Battery powered square drive torque guns complete with a range of sockets.

Tensioning Equipment – Tensioning Pumps, Hoses, connections, we offer both metric and imperial standard sized tensioners and oversized tensioners for coated bolts.

Our torque equipment is regularly inspected to ensure it is kept at the highest standards and within calibration so when it’s required it will always be ready to go at a moment’s notice to meet the demands of a dynamic market.

Our modern facility is equipped with the latest tooling and technology to repair and recertify valves & relating equipment to optimal working standard. Our expansive repair space is furnished to tackle various circumstances of valve overhaul, testing, valve automation and modification.

We offer a quick-turnaround service with overtime working to ensure deadlines are met to best serve our clients and their respective assets. At Gulf Valve, we promote a proactive service as opposed to a reactive one when it comes to repair, maintenance and future performance of the valve; our intuition and understanding of the service and its long term effect on the materials, structure and exposed surfaces advocates us to recommend upgrades to boost product durability and performance to increase their life-cycle to the optimum.

Our knowledge and innovation of industry equipment allows us to modify valve design when necessary, boosting their versatility or sometimes adapting them for a different service/purpose altogether to the benefit of the project. These modifications can take place either on-site or at one of our approved machine shops, all design & calculation activities are controlled and executed by the engineering team at Gulf Valve.

We can modify existing stock to promote considerable cost savings as well as the possibility to minimise system downtime by eliminating factory lead time scenarios to produce prompt and according solutions.

In addition to the standard API & EN hydrostatic and pneumatic valve leak testing, Gulf Valve can offer the most advanced testing to meet the severest of applications and specifications of our customers. Our vast range of test capabilities are as follows:

Looking for something specific?

We are here to help!

Feel free to get in touch with a member of our Sales Team.

©2022 Gulf Valve Piping & Controls Inc

Designed & Developed by Nicholas Ragoobar

Looking for something specific?

We are here to help!

Feel free to get in touch with a member of our Sales Team.

We are a leading valve service contractor, providing customers with a vast range of quality products and an extensive list of professional services.

The one stop shop, for all your valve needs.

©2022 Gulf Valve Piping & Controls Incorporated

Designed & Developed by Nicholas Ragoobar